Lansing Board of Water & Light Retires Last Coal-Fired Plant

December 7, 2022

by APPA News

December 7, 2022

The Lansing Board of Water & Light (BWL) has retired its last coal-fired power plant, which the public power utility said makes it the largest utility in Michigan to generate coal-free power by 2022.

The Nov. 27 retirement of the 160-megawatt (MW) Erickson Power Station aligns with the integrated resource plan BWL released in August 2020 that calls for the utility to deliver 50 percent of its power from clean energy sources by 2030 and to be a carbon dioxide neutral utility by 2040.

“In 2012, BWL burned 1.2 million tons of coal,” Dick Peffley, BWL’s general manager, said in a statement. “Today, 10 years later, BWL’s coal consumption is zero.”

The retirement of the Erickson plant, which began operation in 1973, was preceded by BWL’s retirement of its 350-MW Eckert station in 2020.

BWL is replacing its coal-fired power plants with natural gas-fired plants, as well as a mix of wind and solar generation. Compared with coal, natural gas generation represents an 80 percent reduction in carbon dioxide emissions, as well as a 99.9 percent reduction in sulfur dioxide emissions, BWL said.

BWL replaced the Erickson plant with the 250-MW natural gas-fired, combined-cycle plant Delta Energy Park that came online in August 2022.

BWL also has an agreement with Michigan Public Power Agency to purchase power from DTE Energy’s Belle River coal-fired plant in southeast Michigan’s St. Clair County. DTE has announced plans to convert Belle River to natural gas in 2025-2026.

“These coal-fired plants generated power that allowed Lansing’s automobile industry to grow and flourish and made the Lansing area a terrific place to live, work and raise a family,” Peffley said. “Now it’s time for the next generation of cleaner energy to power the region’s electric vehicle future and beyond. I started my BWL career at Erickson and the plant has had a great run. We appreciate its service to our community and all the employees that kept it operational throughout the decades.”

BWL recently issued an All-Sources request for proposals that the utility plans to use to evaluate electric supply or demand-side resources including wind, solar, battery storage and energy savings programs that can help meet all or part of the BWL’s capacity and energy needs.

The BWL has about 100,000 electric customers, 58,000 water customers, 155 steam customers and 19 chilled water customers.

Reliability, Resiliency, Safety and Affordability Flows from Small Modular Reactor Technology

December 5, 2022

by Peter Maloney

APPA News

December 5, 2022

New nuclear technologies, such as small modular reactors (SMR), have reached a point where they are able to help utilities address growing concerns about fulfilling their core mission: delivering safe, affordable, and reliable electric power.

Several industry trends are challenging utility executives’ abilities to balance those three key objectives.

A July report from the North American Electric Reliability Corp. (NERC) highlighted the growing threats to reliability, including extreme weather events, the growing proliferation of “inverter based resources” such as photovoltaic solar power and energy storage, and increasing reliance on natural gas-fired generation.

The growth of renewable resources aimed at meeting state and federal goals aimed at addressing greenhouse gas emissions has been impressive. In the first half of the year, 24 percent of utility-scale generation in the United States came from renewable sources, according to the Energy Information Administration. However, as NERC pointed out this summer, as renewable resources have proliferated, gas-fired generators are becoming “necessary balancing resources” for reliability, leading to an interdependence that poses “a major new reliability risk.”

In this environment, if utilities are going to stay on track to meet their clean energy targets while providing secure, safe and reliable electric power to meet growing demand, they are going to need a new solution.

“NuScale Power’s SMR technology offers a carbon-free energy solution with features, capability, and performance not found in current nuclear power facilities,” Karin Feldman, Vice President of NuScale’s Program Management Office, said in an interview.

Several utilities have already begun exploring the potential of a new generation of nuclear technology to help them meet both their clean energy and reliability needs as they work toward meeting growing demand.

NuScale’s project portfolio includes a six module, 462-MW VOYGR™ SMR power plant. Utah Associated Municipal Power Systems (UAMPS) plans to develop at the Department of Energy’s (DOE) Idaho National Laboratory in Idaho Falls for their Carbon Free Power Project (CFPP).

NuScale also has memorandums of understanding to evaluate the deployment of its SMR technology with Associated Electric Cooperative in Missouri and Dairyland Power Cooperative in Wisconsin.

“What we bring to the table is a technology that is smaller and simpler; that lowers total costs while providing high reliability and resilience, and greater safety,” said Feldman, who develops and manages NuScale’s portfolio of projects and establishes and maintains project controls, cost estimating, and risk management standards. She is also NuScale’s primary interface with the DOE.

Cost Comparisons

The smaller scale of NuScale’s reactors – 77 MW versus 700 MW or even 1,600 MW or more for conventional reactors – brings several cost advantages, Feldman said. Smaller reactors can be fabricated in a factory, which is cheaper than field fabrication, because it involves repetitive procedures that foster iterative improvement and economies of scale, she said. Smaller reactors also take less time to build, which lowers construction costs.

Because they are modular, an SMR does not force a utility to commit to participation in a nuclear project in the 1,000-MW to 2,000-MW size range. An SMR project can be scaled to meet demand, and modules can be added as demand requires, Feldman said. That helps reduce financial risk for a utility, she said.

Another, related consideration, highlighted by the supply chain disruptions in the wake of the COVID-19 pandemic, is that much of NuScale’s technology can be locally sourced. “We are taking advantage of the U.S. supply chain to the greatest extent possible,” Feldman said. “We have some overseas manufacturers, but we are also engaged to develop additional U.S. capabilities in areas such as large-scale forgings.”

Reliability and Resiliency

Nuclear power plants generally have high reliability, over 92 percent, nearly twice the reliability of coal and natural gas plants, but the smaller, compact design of SMR technology can offer additional reliability advantages, Feldman said. Because NuScale plants are designed to scaled up in incremental steps, if any one of the individual reactors has an issue, the other reactors can continue to generate power, she explained.

NuScale’s SMR technology also enhances resiliency, Feldman said. The design calls for the reactors to be housed in a building below grade, hardening their vulnerability to airplane strikes and very large seismic events, she said.

An SMR plant also is designed with black start capability so that it can restart after a disruption without using the surrounding electric grid. “So, in the event of an emergency, it could be a first responder to the grid, one of the first generators to start up,” Feldman said.

And because the design calls for multiple reactors, a problem with one reactor does not require the entire plant to shut down. An SMR plant can also operate in island mode, serving as a self-sufficient energy source during an emergency, Feldman said.

In some ways, a NuScale SMR power plant resembles a microgrid. In fact, NuScale’s technology team has done a lot of analysis on microgrid capacity, Feldman said, noting that the analysis found that a 154-MW SMR plant could run for 12 years without refueling. “The technology is very good for mission critical functions and activities,” she said.

Safety First

Cost and resiliency are important considerations, but if a power plant, especially a nuclear power plant, is not safe, other considerations pale in comparison.

Safety is built into NuScale’s SMR design, Feldman said. “The SMR has a dual walled vessel design that gives it an unlimited coping period,” she said. “If an incident does occur, the plant can shut down without operator intervention or action and be safe and secure,” she said.

NuScale’s integrated design encompasses the reactor, steam generators and pressurizer and uses the natural action of circulation, eliminating the need for large primary piping and reactor coolant pumps.

If needed, the reactor shuts down and self cools indefinitely without the need for either alternating current or direct current power or additional water. The containment vessel is submerged in a heat sink for core cooling in a below grade reactor pool housed in a Seismic Category 1 reactor building as defined by the U.S. Nuclear Regulatory Commission (NRC). In essence, the unit continues to cool until the decay heat dissipates at which point the reactor is air cooled, Feldman said.

In 2018, the NRC found that NuScale’s SMR safety design eliminates the need for class 1E power, that is, power needed to maintain reactor coolant integrity and remain in a safe shutdown condition.

In August 2020, the NRC approved the overall design of NuScale’s SMR. In a next step, the NRC in July directed staff to issue a final rule certifying NuScale’s SMR design.

If approved, the certification would be published in the Federal Register and have the effect of law, providing even greater comfort to any entities exploring SMR technology to provide clean, emission free, reliable and affordable power, Feldman said.

The rulemaking is on NRC’s docket for a decision in November.

Finally, after a rigorous years long review by the NRC, the Final Safety Evaluation Report (FSER) regarding NuScale’s Emergency Planning Zone (EPZ) methodology was issued. This is another tremendous “first” for NuScale’s technology. With the report’s approval of our methodology, an EPZ that is limited to the site boundary of the power plant is now achievable for a wide range of potential plant sites where a NuScale VOYGR™ SMR power plant could be located.

Salt River Project, Partners Developing Plans for Regional Hydrogen Hub

November 30, 2022

by Peter Maloney

APPA News

November 30, 2022

Salt River Project, along with other members of the Center for an Arizona Carbon-Neutral Economy (AzCaNE), are developing a regional clean hydrogen hub in the Desert Southwest.

The Southwest Clean Hydrogen Innovation Network, or SHINe, submitted a concept paper to seek federal funding from the Department of Energy (DOE) for key clean hydrogen-focused initiatives, including production, processing, storage, delivery systems, community benefits and other enabling infrastructure.

Arizona, the Navajo Nation and Nevada have abundant sunshine that can be a source of solar power to produce clean hydrogen. In addition, Arizona has the nation’s largest nuclear power plant, which can also be used as a source of clean energy for hydrogen production, AzCaNE members said.

“The SHINe network includes salt cavern storage, heavy-duty transportation, and distribution technologies that will help accelerate the use of clean hydrogen as a source of low-carbon energy powering the economy,” Ellen Stechel, AzCaNE’s executive director, said in a statement.

When fully operational, SHINe aims to help support DOE’s vision of a regional clean hydrogen hub that provides clean energy for hard-to-abate carbon emissions in the transportation, industrial and electricity sectors while maintaining a reliable and resilient electric grid.

The DOE has noted that up to $7 billion is available to fund the development of between six and 10 regional clean hydrogen hubs. Funding for regional clean hydrogen hubs was outlined as part of the Infrastructure Investment and Jobs Act, which authorized up to $8 billion for at least four regional clean hydrogen hubs.

In February, the DOE announced two requests for information to collect feedback from stakeholders to inform the implementation and design of the infrastructure law’s Regional Hydrogen Hub and the Electrolysis and Clean Hydrogen Manufacturing and Recycling Programs.

In March, the governors of Colorado, New Mexico, Utah and Wyoming signed a memorandum of understanding for the development of a regional clean hydrogen hubs.

In September, Maine and Rhode Island joined a multi-state clean hydrogen hub in the New England/Mid-Atlantic region. The New York-led coalition already included Connecticut, Massachusetts and New Jersey.

Clark Public Utilities, Pend Oreille Public Utility District Enter Hydro Power Sales Agreement

November 29, 2022

by Paul Ciampoli

APPA News Director

November 29, 2022

Clark Public Utilities and the Pend Oreille Public Utility District (PUD) have entered into a long-term power sales agreement under which Pend Oreille PUD will sell all energy produced by the Box Canyon hydroelectric project in Washington State to Clark Public Utilities from Jan. 1, 2026, through December 2041, with contract extensions available under mutual agreement.

The Clark Public Utilities Board of Commissioners unanimously approved the 16-year power sales agreement on Oct. 18 following unanimous approval by Pend Oreille PUD’s Board of Commissioners on Oct. 4. Clark Public Utilities and Pend Oreille PUD are both located in Washington State.

The agreement “reflects a long tradition of collaboration and cooperation among the state’s customer-owned public utility districts to deliver reliable, responsible power to the local communities served, and is a critical piece of Clark Public Utilities’ strategy to meet state-mandated emissions reduction targets ahead of schedule,” the public power utilities said.

The Box Canyon Dam averages approximately 50 megawatts of generation annually.

Clark Public Utilities will pay the forecasted dam costs and debt service payments associated with the power plant modernization and the environmental mitigation modifications made by Pend Oreille PUD over the last decade.

The contract secures a stable, long-term customer for Pend Oreille PUD, which, since 2019 has undertaken a multi-phase remarketing effort of its energy supply, both in anticipation of and following the closure of the Ponderay Newsprint Company, which represented about 70 percent of the utility’s historical load.

Reliability, Resiliency, Safety and Affordability Flows from Small Modular Reactor Technology

November 28, 2022

by Peter Maloney

APPA News

November 28, 2022

New nuclear technologies, such as small modular reactors (SMR), have reached a point where they are able to help utilities address growing concerns about fulfilling their core mission: delivering safe, affordable, and reliable electric power.

Several industry trends are challenging utility executives’ abilities to balance those three key objectives.

A July report from the North American Electric Reliability Corp. (NERC) highlighted the growing threats to reliability, including extreme weather events, the growing proliferation of “inverter based resources” such as photovoltaic solar power and energy storage, and increasing reliance on natural gas-fired generation.

The growth of renewable resources aimed at meeting state and federal goals aimed at addressing greenhouse gas emissions has been impressive. In the first half of the year, 24 percent of utility-scale generation in the United States came from renewable sources, according to the Energy Information Administration. However, as NERC pointed out this summer, as renewable resources have proliferated, gas-fired generators are becoming “necessary balancing resources” for reliability, leading to an interdependence that poses “a major new reliability risk.”

In this environment, if utilities are going to stay on track to meet their clean energy targets while providing secure, safe and reliable electric power to meet growing demand, they are going to need a new solution.

“NuScale Power’s SMR technology offers a carbon-free energy solution with features, capability, and performance not found in current nuclear power facilities,” Karin Feldman, Vice President of NuScale’s Program Management Office, said in an interview.

Several utilities have already begun exploring the potential of a new generation of nuclear technology to help them meet both their clean energy and reliability needs as they work toward meeting growing demand.

NuScale’s project portfolio includes a six module, 462-MW VOYGR™ SMR power plant. Utah Associated Municipal Power Systems (UAMPS) plans to develop at the Department of Energy’s (DOE) Idaho National Laboratory in Idaho Falls for their Carbon Free Power Project (CFPP).

NuScale also has memorandums of understanding to evaluate the deployment of its SMR technology with Associated Electric Cooperative in Missouri and Dairyland Power Cooperative in Wisconsin.

“What we bring to the table is a technology that is smaller and simpler; that lowers total costs while providing high reliability and resilience, and greater safety,” said Feldman, who develops and manages NuScale’s portfolio of projects and establishes and maintains project controls, cost estimating, and risk management standards. She is also NuScale’s primary interface with the DOE.

Cost Comparisons

The smaller scale of NuScale’s reactors – 77 MW versus 700 MW or even 1,600 MW or more for conventional reactors – brings several cost advantages, Feldman said. Smaller reactors can be fabricated in a factory, which is cheaper than field fabrication, because it involves repetitive procedures that foster iterative improvement and economies of scale, she said. Smaller reactors also take less time to build, which lowers construction costs.

Because they are modular, an SMR does not force a utility to commit to participation in a nuclear project in the 1,000-MW to 2,000-MW size range. An SMR project can be scaled to meet demand, and modules can be added as demand requires, Feldman said. That helps reduce financial risk for a utility, she said.

Another, related consideration, highlighted by the supply chain disruptions in the wake of the COVID-19 pandemic, is that much of NuScale’s technology can be locally sourced. “We are taking advantage of the U.S. supply chain to the greatest extent possible,” Feldman said. “We have some overseas manufacturers, but we are also engaged to develop additional U.S. capabilities in areas such as large-scale forgings.”

Reliability and Resiliency

Nuclear power plants generally have high reliability, over 92 percent, nearly twice the reliability of coal and natural gas plants, but the smaller, compact design of SMR technology can offer additional reliability advantages, Feldman said. Because NuScale plants are designed to scaled up in incremental steps, if any one of the individual reactors has an issue, the other reactors can continue to generate power, she explained.

NuScale’s SMR technology also enhances resiliency, Feldman said. The design calls for the reactors to be housed in a building below grade, hardening their vulnerability to airplane strikes and very large seismic events, she said.

An SMR plant also is designed with black start capability so that it can restart after a disruption without using the surrounding electric grid. “So, in the event of an emergency, it could be a first responder to the grid, one of the first generators to start up,” Feldman said.

And because the design calls for multiple reactors, a problem with one reactor does not require the entire plant to shut down. An SMR plant can also operate in island mode, serving as a self-sufficient energy source during an emergency, Feldman said.

In some ways, a NuScale SMR power plant resembles a microgrid. In fact, NuScale’s technology team has done a lot of analysis on microgrid capacity, Feldman said, noting that the analysis found that a 154-MW SMR plant could run for 12 years without refueling. “The technology is very good for mission critical functions and activities,” she said.

Safety First

Cost and resiliency are important considerations, but if a power plant, especially a nuclear power plant, is not safe, other considerations pale in comparison.

Safety is built into NuScale’s SMR design, Feldman said. “The SMR has a dual walled vessel design that gives it an unlimited coping period,” she said. “If an incident does occur, the plant can shut down without operator intervention or action and be safe and secure,” she said.

NuScale’s integrated design encompasses the reactor, steam generators and pressurizer and uses the natural action of circulation, eliminating the need for large primary piping and reactor coolant pumps.

If needed, the reactor shuts down and self cools indefinitely without the need for either alternating current or direct current power or additional water. The containment vessel is submerged in a heat sink for core cooling in a below grade reactor pool housed in a Seismic Category 1 reactor building as defined by the U.S. Nuclear Regulatory Commission (NRC). In essence, the unit continues to cool until the decay heat dissipates at which point the reactor is air cooled, Feldman said.

In 2018, the NRC found that NuScale’s SMR safety design eliminates the need for class 1E power, that is, power needed to maintain reactor coolant integrity and remain in a safe shutdown condition.

In August 2020, the NRC approved the overall design of NuScale’s SMR. In a next step, the NRC in July directed staff to issue a final rule certifying NuScale’s SMR design.

If approved, the certification would be published in the Federal Register and have the effect of law, providing even greater comfort to any entities exploring SMR technology to provide clean, emission free, reliable and affordable power, Feldman said.

The rulemaking is on NRC’s docket for a decision in November.

Finally, after a rigorous years long review by the NRC, the Final Safety Evaluation Report (FSER) regarding NuScale’s Emergency Planning Zone (EPZ) methodology was issued. This is another tremendous “first” for NuScale’s technology. With the report’s approval of our methodology, an EPZ that is limited to the site boundary of the power plant is now achievable for a wide range of potential plant sites where a NuScale VOYGR™ SMR power plant could be located.

Small Modular Reactor Technology Delivers Reliability, Resiliency, Safety and Affordability

November 22, 2022

by Peter Maloney

APPA News

November 22, 2022

New nuclear technologies, such as small modular reactors (SMR), have reached a point where they are able to help utilities address growing concerns about fulfilling their core mission: delivering safe, affordable, and reliable electric power.

Several industry trends are challenging utility executives’ abilities to balance those three key objectives.

A July report from the North American Electric Reliability Corp. (NERC) highlighted the growing threats to reliability, including extreme weather events, the growing proliferation of “inverter based resources” such as photovoltaic solar power and energy storage, and increasing reliance on natural gas-fired generation.

The growth of renewable resources aimed at meeting state and federal goals aimed at addressing greenhouse gas emissions has been impressive. In the first half of the year, 24 percent of utility-scale generation in the United States came from renewable sources, according to the Energy Information Administration. However, as NERC pointed out this summer, as renewable resources have proliferated, gas-fired generators are becoming “necessary balancing resources” for reliability, leading to an interdependence that poses “a major new reliability risk.”

In this environment, if utilities are going to stay on track to meet their clean energy targets while providing secure, safe and reliable electric power to meet growing demand, they are going to need a new solution.

“NuScale Power’s SMR technology offers a carbon-free energy solution with features, capability, and performance not found in current nuclear power facilities,” Karin Feldman, Vice President of NuScale’s Program Management Office, said in an interview.

Several utilities have already begun exploring the potential of a new generation of nuclear technology to help them meet both their clean energy and reliability needs as they work toward meeting growing demand.

NuScale’s project portfolio includes a six module, 462-MW VOYGR™ SMR power plant. Utah Associated Municipal Power Systems (UAMPS) plans to develop at the Department of Energy’s (DOE) Idaho National Laboratory in Idaho Falls for their Carbon Free Power Project (CFPP).

NuScale also has memorandums of understanding to evaluate the deployment of its SMR technology with Associated Electric Cooperative in Missouri and Dairyland Power Cooperative in Wisconsin.

“What we bring to the table is a technology that is smaller and simpler; that lowers total costs while providing high reliability and resilience, and greater safety,” said Feldman, who develops and manages NuScale’s portfolio of projects and establishes and maintains project controls, cost estimating, and risk management standards. She is also NuScale’s primary interface with the DOE.

Cost Comparisons

The smaller scale of NuScale’s reactors – 77 MW versus 700 MW or even 1,600 MW or more for conventional reactors – brings several cost advantages, Feldman said. Smaller reactors can be fabricated in a factory, which is cheaper than field fabrication, because it involves repetitive procedures that foster iterative improvement and economies of scale, she said. Smaller reactors also take less time to build, which lowers construction costs.

Because they are modular, an SMR does not force a utility to commit to participation in a nuclear project in the 1,000-MW to 2,000-MW size range. An SMR project can be scaled to meet demand, and modules can be added as demand requires, Feldman said. That helps reduce financial risk for a utility, she said.

Another, related consideration, highlighted by the supply chain disruptions in the wake of the COVID-19 pandemic, is that much of NuScale’s technology can be locally sourced. “We are taking advantage of the U.S. supply chain to the greatest extent possible,” Feldman said. “We have some overseas manufacturers, but we are also engaged to develop additional U.S. capabilities in areas such as large-scale forgings.”

Reliability and Resiliency

Nuclear power plants generally have high reliability, over 92 percent, nearly twice the reliability of coal and natural gas plants, but the smaller, compact design of SMR technology can offer additional reliability advantages, Feldman said. Because NuScale plants are designed to scaled up in incremental steps, if any one of the individual reactors has an issue, the other reactors can continue to generate power, she explained.

NuScale’s SMR technology also enhances resiliency, Feldman said. The design calls for the reactors to be housed in a building below grade, hardening their vulnerability to airplane strikes and very large seismic events, she said.

An SMR plant also is designed with black start capability so that it can restart after a disruption without using the surrounding electric grid. “So, in the event of an emergency, it could be a first responder to the grid, one of the first generators to start up,” Feldman said.

And because the design calls for multiple reactors, a problem with one reactor does not require the entire plant to shut down. An SMR plant can also operate in island mode, serving as a self-sufficient energy source during an emergency, Feldman said.

In some ways, a NuScale SMR power plant resembles a microgrid. In fact, NuScale’s technology team has done a lot of analysis on microgrid capacity, Feldman said, noting that the analysis found that a 154-MW SMR plant could run for 12 years without refueling. “The technology is very good for mission critical functions and activities,” she said.

Safety First

Cost and resiliency are important considerations, but if a power plant, especially a nuclear power plant, is not safe, other considerations pale in comparison.

Safety is built into NuScale’s SMR design, Feldman said. “The SMR has a dual walled vessel design that gives it an unlimited coping period,” she said. “If an incident does occur, the plant can shut down without operator intervention or action and be safe and secure,” she said.

NuScale’s integrated design encompasses the reactor, steam generators and pressurizer and uses the natural action of circulation, eliminating the need for large primary piping and reactor coolant pumps.

If needed, the reactor shuts down and self cools indefinitely without the need for either alternating current or direct current power or additional water. The containment vessel is submerged in a heat sink for core cooling in a below grade reactor pool housed in a Seismic Category 1 reactor building as defined by the U.S. Nuclear Regulatory Commission (NRC). In essence, the unit continues to cool until the decay heat dissipates at which point the reactor is air cooled, Feldman said.

In 2018, the NRC found that NuScale’s SMR safety design eliminates the need for class 1E power, that is, power needed to maintain reactor coolant integrity and remain in a safe shutdown condition.

In August 2020, the NRC approved the overall design of NuScale’s SMR. In a next step, the NRC in July directed staff to issue a final rule certifying NuScale’s SMR design.

If approved, the certification would be published in the Federal Register and have the effect of law, providing even greater comfort to any entities exploring SMR technology to provide clean, emission free, reliable and affordable power, Feldman said.

The rulemaking is on NRC’s docket for a decision in November.

Finally, after a rigorous years long review by the NRC, the Final Safety Evaluation Report (FSER) regarding NuScale’s Emergency Planning Zone (EPZ) methodology was issued. This is another tremendous “first” for NuScale’s technology. With the report’s approval of our methodology, an EPZ that is limited to the site boundary of the power plant is now achievable for a wide range of potential plant sites where a NuScale VOYGR™ SMR power plant could be located.

DOE Announces Conditional Selection of Calif. Nuclear Plant to Receive Funding

November 21, 2022

by Paul Ciampoli

APPA News Director

November 21, 2022

The U.S. Department of Energy (DOE) on Nov. 21 announced the conditional selection of the Diablo Canyon nuclear power plant in California to receive the first round of funding from the Civil Nuclear Credit (CNC) Program.

Units 1 and 2 at the Diablo Canyon Power Plant (DCPP) were scheduled to be decommissioned in 2024 and 2025, but the conditional award of credits, valued at up to $1.1 billion, creates a path forward for Diablo Canyon to remain open. Final terms are subject to negotiation and finalization by DOE.

Funded by President Biden’s Infrastructure Law, the $6 billion CNC program aims to help preserve the existing U.S. nuclear reactor fleet.

DOE noted that shifting energy markets and other economic factors have resulted in the early closures of 13 commercial reactors across the United States since 2013.

Owned and operated by Pacific Gas and Electric Company (PG&E), Diablo Canyon produces approximately 16 GWh of electricity annually.

PG&E filed its application for federal funding on September 2, 2022, the same day California Governor Gavin Newsom signed Senate Bill 846 into law, seeking to extend operations at DCPP in San Luis Obispo County for five years beyond its current license expiration in 2025.

Last month, the state authorized a loan of up to $1.4 billion from the Department of Water Resources to PG&E to support extending operations at the plant. SB 846 further directed PG&E to pursue funds from DOE, and any other potentially available federal funds, to pay back the loan and lower costs for customers should the plant’s operating license be extended.

DOE said that the first CNC award cycle prioritized reactors facing the most imminent threat of closure, limiting applications to reactors that had already announced intentions to cease operations due to economic factors.

The second CNC award cycle will prioritize reactors that are projected to shut down due to economic factors within the next four years.

DOE is expected to begin accepting applications for the second cycle of CNC funding in January 2023.

Click here for additional details about the CNC Program and the upcoming second award cycle.

Combined Cycle Gas Plants Reverse Trend, Adding Nearly 8 GW This Year: EIA

November 14, 2022

by Peter Maloney

APPA News

November 14, 2022

By the end of the year, eight natural gas-fired combined-cycle gas turbine (CCGT) plants have either come online, reversing a four-year decline in CCGT start-ups, according to the Energy Information Administration (EIA).

The new plants will add 7,775 megawatts (MW) of generating capacity to the electric grid, according to the latest estimates and data from EIA’s Monthly Electric Generator Inventory. The EIA expects CCGT capacity to reach almost 290 gigawatts (GW) by year-end, or 24 percent of total U.S. generating capacity.

Output from CCGT plants, which use combine a gas and steam turbine in a single plant, will likely rise from the 1,326,278 gigawatt hours (GWh) they generated in 2021, which was 32 percent of total electric generation last year. Coal-fired generation ranked second at 22 percent of total generation and nuclear power was third at 19 percent in 2021.

The EIA expects 4,215 MW of CCGT capacity will be added in 2023, when five new plants are slated to open. All of those facilities are under construction and expected to enter service before the end of 2023.

About half of the existing CCGT fleet currently operating entered service between 2000 and 2006. CCGT additions have continued since then albeit it at a slower pace. This year’s additions are about 80 percent below the record level of CCGT additions set in 2002 and 2003, the EIA noted.

Seven of the eight CCGT plants opening this year are either in the upper Midwest or in Florida where they are being built to meet rising demand for electricity and to replace retiring coal-fired power plants, the EIA said.

In Michigan, 1,403 MW of new CCGT capacity will replace the 1,560 MW of existing coal-fired generating capacity scheduled to retire this year.

In Florida, the 2,222 MW of new CCGT capacity will replace 1,486 MW of coal-fired capacity retiring this year.

Three CCGT plants, with 3,918 MW of capacity, are opening this year in the PJM Interconnection region where they will help replace the 5,346 MW of coal-fired capacity in PJM that is retiring this year and the 3,774 MW of coal capacity scheduled to retire next year, EIA said.

TVA, Other Utilities Launch Southeast Hydrogen Hub Effort

November 4, 2022

by Paul Ciampoli

APPA News Director

November 4, 2022

A newly formed coalition including the Tennessee Valley Authority (TVA) and other major utilities recently announced its plan to pursue federal financial support for a Southeast Hydrogen Hub.

The coalition will respond to the recently announced funding opportunity from the U.S. Department of Energy, which includes $8 billion for regional hydrogen hubs and is part of the Infrastructure Investment and Jobs Act.

Along with TVA, the other members of the coalition include Dominion Energy, Duke Energy, Louisville Gas & Electric Company and Kentucky Utilities Company (LG&E and KU), Southern Company, along with Battelle and others.

Other members of the Southeast Hydrogen Hub coalition will include a growing list of hydrogen users from a variety of industries in Alabama, Georgia, Kentucky, North Carolina, South Carolina, and Tennessee. The coalition expects its membership to grow.

Hydrogen may be poised to play a major role in addressing climate change and could be essential for each coalition member to meet its stated carbon-reduction goals.

TVA, for example, is looking to achieve 70% carbon reduction by 2030 and approximately 80% carbon reduction by 2035.

“By working together, the coalition can focus on developing scalable, integrated projects at key locations across the entire Southeast in support of these carbon-reduction goals and encourage the broad-based development of a regional energy ecosystem that will allow members to deploy hydrogen as a decarbonization solution for customers and communities,” a news release from the coalition members said.

Maine and Rhode Island recently joined a multi-state clean hydrogen hub in the New England/Mid-Atlantic region.

Earlier this year, governors of Colorado, New Mexico, Utah and Wyoming have joined forces in signing a memorandum of understanding (MOU) for the development of a regional clean hydrogen hubs.

Under the MOU the states agreed to compete jointly for a portion of the $8 billion allocated in the federal Infrastructure Investment and Jobs Act for hydrogen hubs.

Several West Coast utilities, including the Los Angeles Department of Water and Power (LADWP) and Douglas County PUD in Washington, have recently embarked on projects aimed at furthering the feasibility of using hydrogen fuels to offset the use of traditional fossil fuels.

To help public power utilities understand the potential — and the limitations — of hydrogen, and why they should get involved, the American Public Power Association developed Understanding Hydrogen: Trends and Use Cases.

NOAA Winter Outlook Sees Warmer, Drier South with Ongoing La Nina

November 3, 2022

by Paul Ciampoli

APPA News Director

November 3, 2022

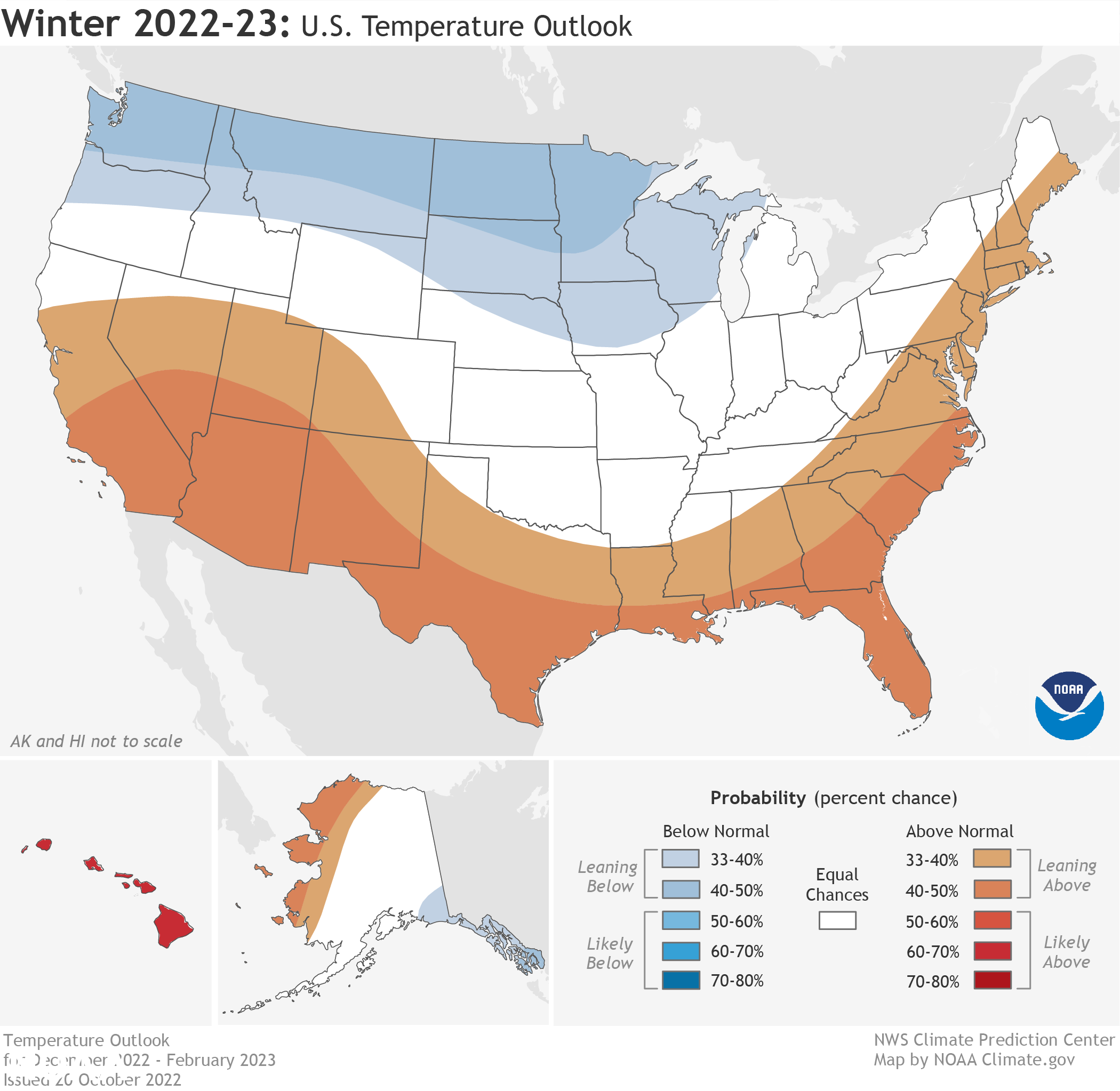

This year La Niña returns for the third consecutive year, driving warmer-than-average temperatures for the Southwest and along the Gulf Coast and eastern seaboard, according to the National Oceanic and Atmospheric Administration’s (NOAA) U.S. Winter Outlook released by the Climate Prediction Center, a division of the National Weather Service.

Starting in December 2022 through February 2023, NOAA predicts drier-than-average conditions across the South with wetter-than-average conditions for areas of the Ohio Valley, Great Lakes, northern Rockies and Pacific Northwest.

NOAA forecasters, in collaboration with the National Integrated Drought Information System (NIDIS), continue to monitor extreme, ongoing drought conditions that have persisted in the Western U.S. since late 2020, as well as parts of the central U.S. where historic low-water conditions are currently present.

“Drought conditions are now present across approximately 59% of the country, but parts of the Western U.S and southern Great Plains will continue to be the hardest hit this winter,” said Jon Gottschalck, chief, Operational Prediction Branch, NOAA’s Climate Prediction Center. “With the La Niña climate pattern still in place, drought conditions may also expand to the Gulf Coast.”

Widespread extreme drought continues to persist across much of the West, the Great Basin, and the central-to-southern Great Plains.

Drought is expected to impact the middle and lower Mississippi Valley this winter.

Drought development is expected to occur across the South-central and Southeastern U.S., while drought conditions are expected to improve across the Northwestern U.S. over the coming months.

With respect to temperatures, the greatest chance for warmer-than-average conditions are in western Alaska, and the Central Great Basin and Southwest extending through the Southern Plains.

Warmer-than-average temperatures are also favored in the Southeastern U.S. and along the Atlantic coast. Below-normal temperatures are favored from the Pacific Northwest eastward to the western Great Lakes and the Alaska Panhandle.

With respect to precipitation, wetter-than-average conditions are most likely in western Alaska, the Pacific Northwest, northern Rockies, Great Lakes and Ohio Valley.

The greatest chances for drier-than-average conditions are forecast in portions of California, the Southwest, the southern Rockies, southern Plains, Gulf Coast and much of the Southeast.

The remainder of the U.S. falls into the category of equal chances for below-, near-, or above-average seasonal total precipitation.